Product Description

PLC controlled logic functioning

Complete with:

- Thermostatic glue control with automatic standby and temperature Indicator

- Light-up LED buttons for machine operating units selection

- Diagnostic system with messages for machine use and maintenance

- Statistical operating data: total hours of machine use, total and partial meters of edge used

• Automatic panel feeding by steel core toothed belt

• 3 position infeed fence: 0-1-2 mm (according to edge thickness)

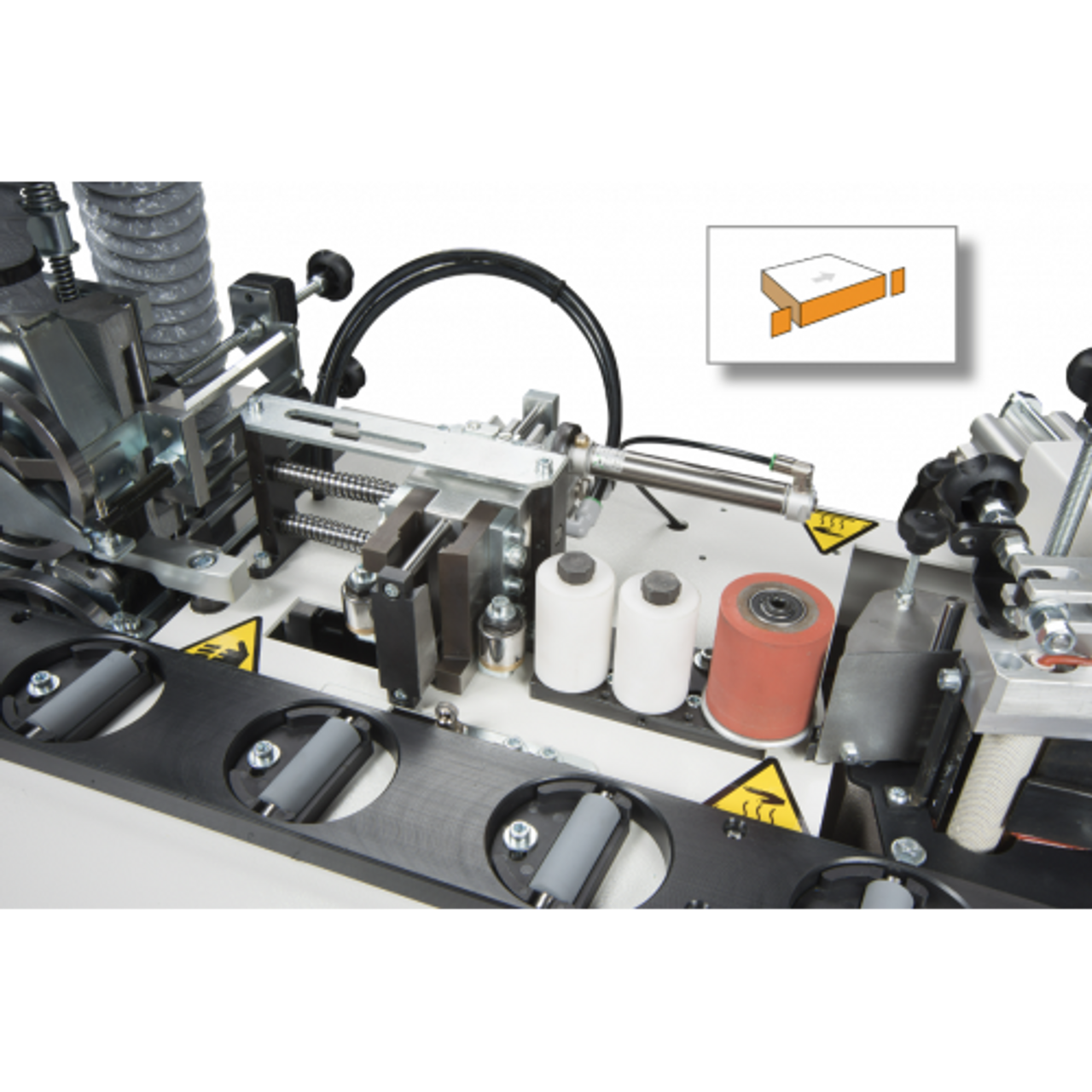

• Pneumatic edge cutting shears from coil

• Teflon-coated glue pot fitted with 6 electrical heating elements (4 in the glue pot, 1 in the turret and 1 inside

the glue spreading roller) for uniform glue temperature. Motorized glue spreading roller.

• 3 pressure rollers (1 rubber and 2 nylon)

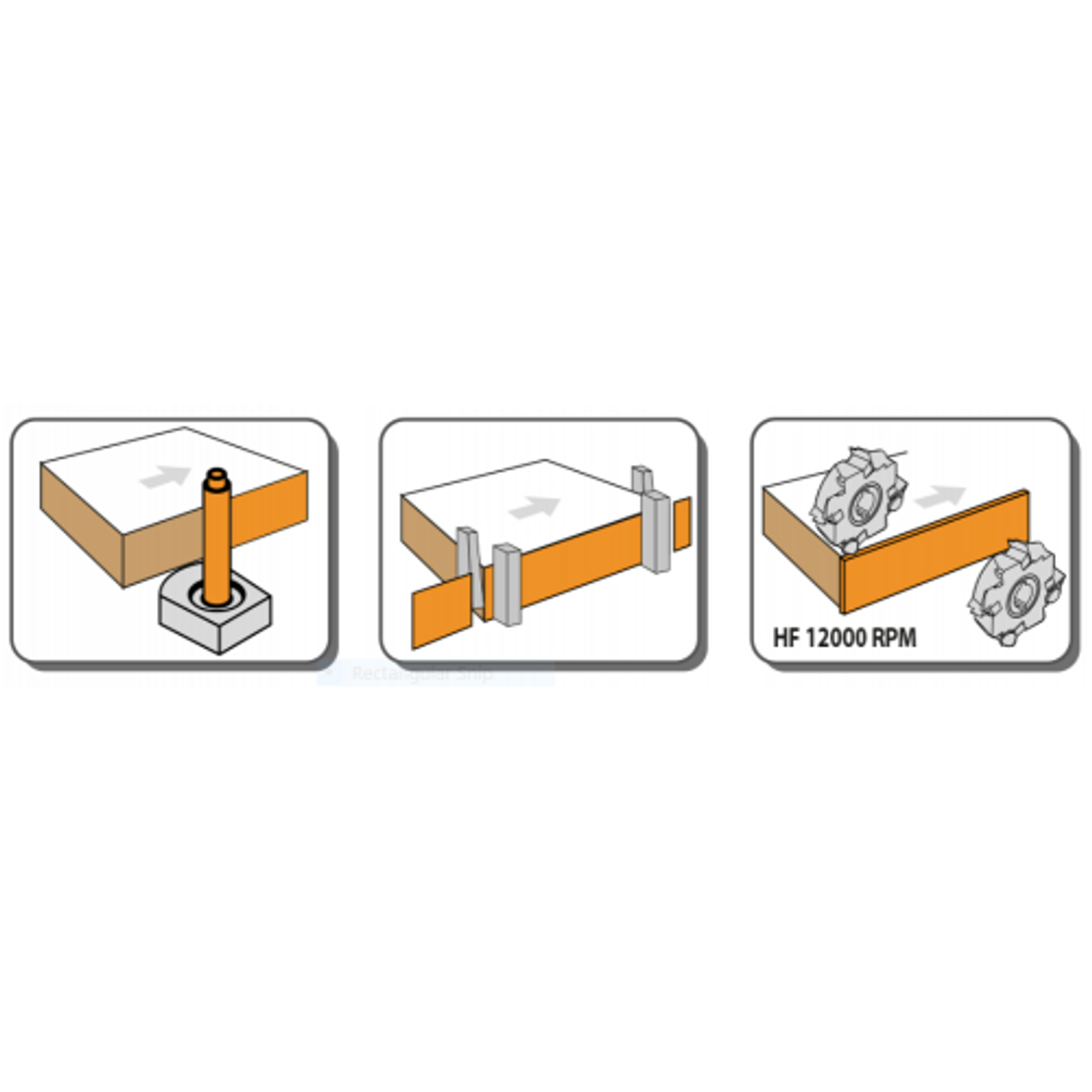

• Pneumatic End trimming unit with shears and follow-up system (front and rear edges), can be excluded from the control panel.

• One motor flush trimming unit (top-bottom) 10.300 RPM with Z4 Ø 75 mm cutterblocks, WIDIA disposable

knives, combined profile: straight/radius 2 mm/bevel with vertical disc copiers and numeric dials

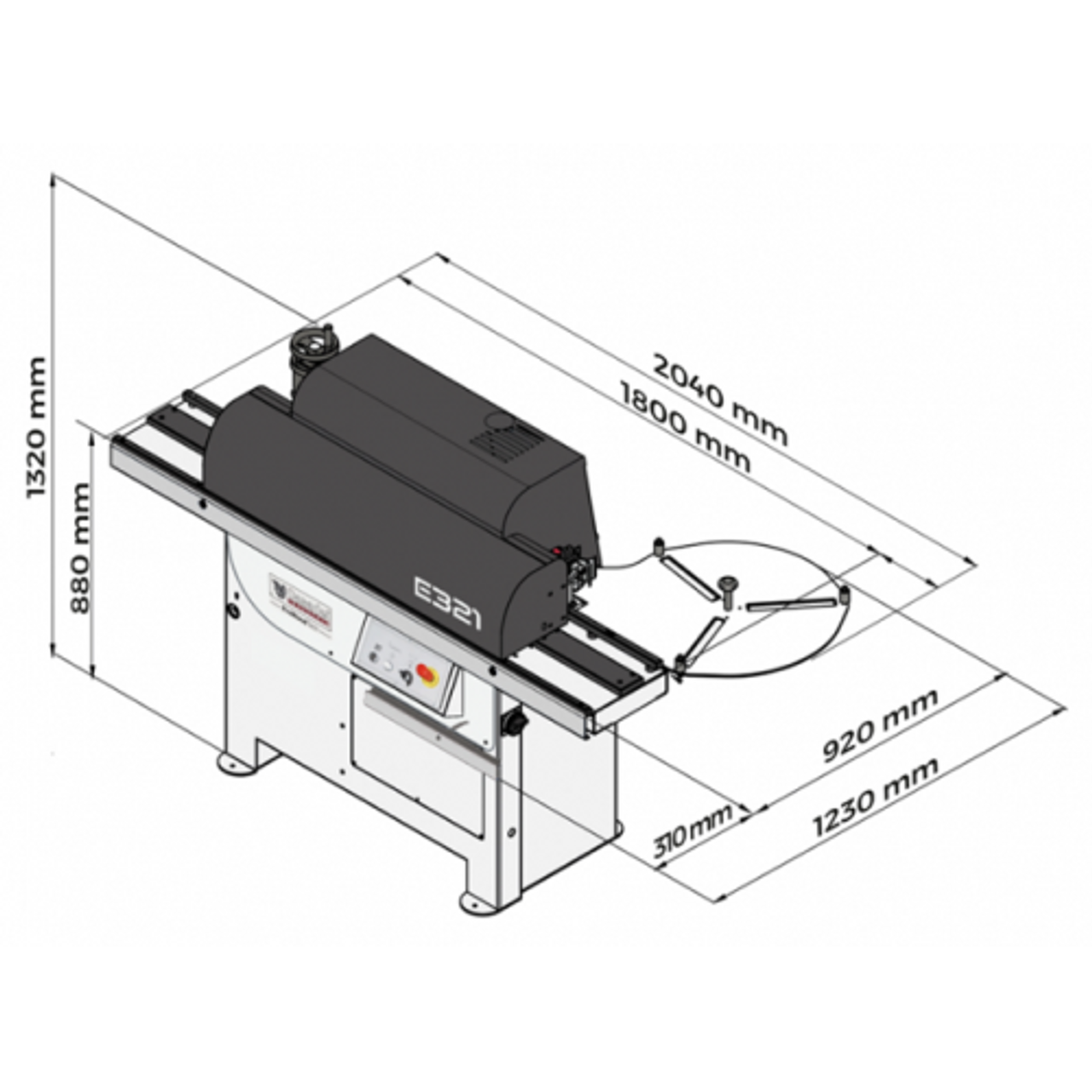

• Working table length 1.800 mm with 7 adjustable rollers and Polizene sliding fences

• Front extensible support for large panels with Polizene sliding fences